Procedure & Welder Qualification

Hot Tapping and in Service Welding Procedure Development Supervision and Monitoring

This high risk activity requires safe conservative but confident development with the aim of efficient execution in demanding situations. Hot tap simulations are managed, modelled and qualified to comply with all code and customer specifications.

Welder Qualifications

We come to you, monitor the welding , provide visual examination & reporting, arrange testing, review results and provide fully documented Welder Qualification Records to all codes, standards and customer specifications. We can even provide a management service to keep your welders up to date.

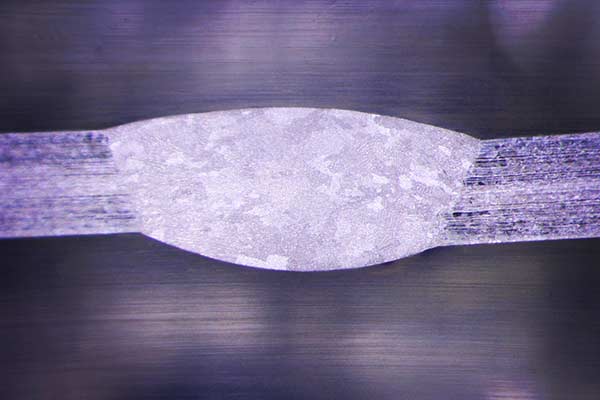

Welding Procedure Development and Qualification

Your application, economics and code compliance are key considerations when developing and qualifying WPSs. Easy to read formats, keeping the usability characteristic in the middle of a broad window ensuring ease of use.

Consumable Qualification and Selection

Independent experienced advice and qualification of welding consumables. Untangling the complexity of choice around the competing issues of mechanical properties, use-ability, country of origin, availability, storage and life considerations, dilution, heat treatment & economics.